H Fabric

Flexible Multifilament for Troughing

Flexible Multifilament for Troughing

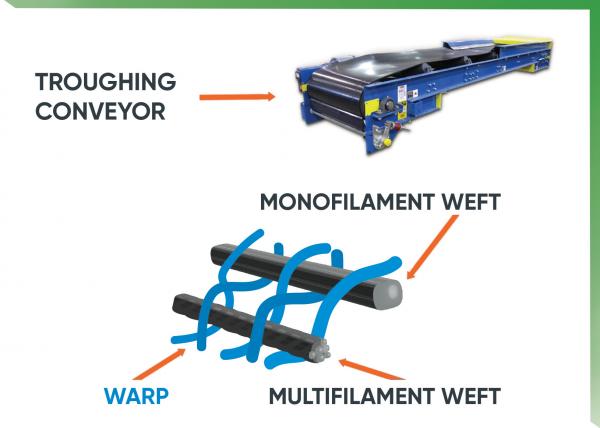

Design elements in conveyor belt construction impact running characteristics. Decisions about the fabric weave, composition and thickness can be especially complex and have a direct impact on the performance of a particular belt type. Today we will talk about the laterally flexible “H” fabric.

Fabrics are made up of running length warp yarns, and weft yarns across the width. The warp yarns must be flexible to wrap around the drive pulley, while weft yarns may be flexible or rigid depending on the conveyor configuration. H is an internal part designation used to describe a fabric that is laterally flexible. This is particularly desirable if your belt needs to be able to fold into a trough for containment or shaping.

Mol Belting’s “H” fabric is flexible due to the multifilaments. A monofilament (see article on “R” fabric) is strong and rigid as it is composed of a single yarn run straight across the width of the belt. Conversely, a multifilament is made of several yarns to provide similar strength with better flexibility due to the finer yarns.

Part numbers with an “AH” fabric have a laterally flexible construction with the addition of anti-static conductive fibers in the running direction of the belt. Contact one of our sales representatives to learn more about which belt is best suited for your conveyor application.