R Fabric

What is R fabric, and why is it used?

What is R fabric, and why is it used?

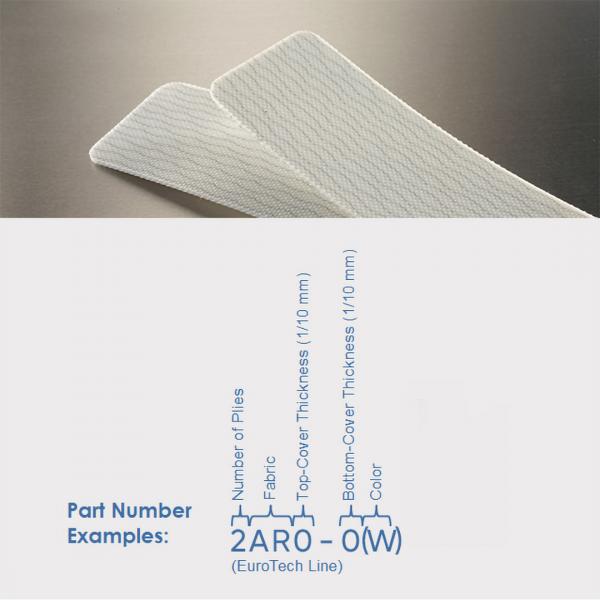

There is a lot of purpose and design that goes into every conveyor belt. Decisions about the fabric weave, composition and thickness can be especially complex and have a direct impact on the performance of a particular belt type. The most common fabric in Mol Belting’s product line is what we call an “R” fabric.

R is an internal part designation used to describe a fabric that is laterally rigid. This means that a belt will have a limited resistance to bending across the width. This is due to the .25mm thick monofilaments that form the weft yarns of the fabric.

Mol Belting’s “R” fabric is made from polyester for its strength, chemical and mildew resistance, and low cost compared to other synthetic materials. The plain weave pattern is a strong general purpose construction that also keeps the cost low. The simplicity of the design makes this a good standard when trade-offs are not necessary to deal with specific application issues.

Part numbers with an “AR” fabric have a laterally rigid construction with the addition of anti-static conductive fibers in the warp (running) direction of the belt. Contact one of our sales representatives to learn more about which belt is best suited for your conveyor application. You can also view and compare our standard conveyor belts by fabric type and other parameters by using our belt finder tool.