Custom Belt Fabrication For Your Toughest Applications

Mol Belting Systems is a company known for its outstanding fabrication abilities. We offer world-class, comprehensive solutions to meet your specific belting needs. Our fabrication techniques are continuously refined, allowing us to engineer solutions for the most demanding of applications.

CNC Cutting Tables

Our CNC Cutting tables are extremely versatile machines. Having a large CNC Cutting table and a CNC indexing table allows us significantly greater flexibility than any other belting company. Nearly any design can be cut or routered from a wide selection of belting, fabrics, leathers, and many other flat materials – allowing our customer to create right along with us

Printing and Coating

Mol Belting’s state-of-the-art digital belt printing system provides custom messaging across any application. Whether you’re looking for MessageWrap™ for grocery store checkout counters or logos printed on fitness belting, our color printer is an economical and hygienic solution. Our permanent ink requires no down-time for cooling and the coating helps protect the print quality for years to come.

Cover Profiles

Mol Belting has the capability of adding custom profiles to the top or bottom cover of many of our PVC and Polyurethane belts. Standard products can be resurfaced with one of ten profiles to fine-tune the grip needed for your application.

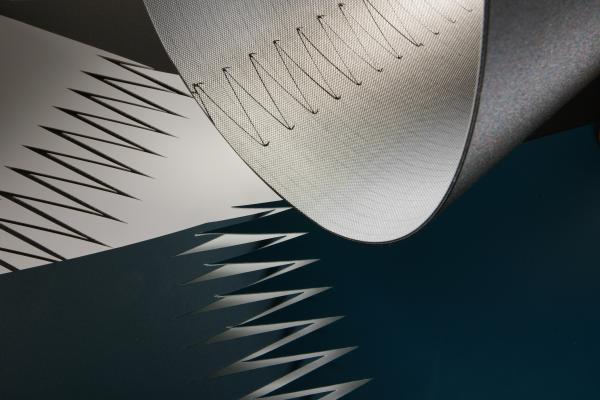

Lacing

Lace is a term for the mechanical fasteners typically used to attach two ends of a conveyor belt. Mol Belting Systems is a proud distributor of Flexco products and uses their lace for nearly all of our factory work. We can help you find the fasteners you need and offer multiple fastening methods to suit your conveyance needs.

Guides

A guide is an accessory that can be welded or glued to the bottom or top of your conveyor belt. On the bottom of a belt, a guide aides in tracking a belt as it moves along the conveyor. Guides can also be added to the top of the belt for product containment. We offer many different sizes and colors of solid and notched guides. Most guides are tapered at the bottom. This is called a v-guide.

Endlessing

Conveyor belts require tension to move on a conveyor. Endlessing is the processing on join two ends to form a continuous loop on the conveyor so that tension can be applied to cause the belt to turn on the conveyor. Mol Belting has many different endless options available to suit your specific needs.

Sanitary Design

ThermoGienic™ Cleats

Our unique fabrication process produces an extremely sanitary end product that is free of inside corners, niches or weld splatter. The cleats are permanently attached to the base belt forming a smooth 1/8" radius around the entire perimeter of the cleat base. This innovative process ensures that your belts will remain easily cleanable to a microbial level. ThermoGienic™ cleats are part of the Mol Belting advantage as they are sanitary by design.

ThermoGienic™ Synchronized Sidewall

For controlled containment of product, we offer a hygienic sidewall. Our ThermoGienic™ sidewall is synchronously welded to the thermoplastic base belt. This results in a smooth consistent finish with a lower footprint for clean-ability with superior strength and minimum pulley capabilities.

Edgecap

Exposed fabric is absorbent. The liquids soaked up by a fabric can harbor bacteria and are difficult to sanitize. Edgecap seals the outside edge by removing exposed fabric and replacing the outside edge with a solid thermoplastic, resulting in an easy-to-clean edge that is non-absorbent. Edgecap also eliminates edge fray.