Wicking

What is wicking and why does it matter?

What is wicking and why does it matter?

Wicking is a common term in conveyor belting. You might hear that a belt has anti-wicking properties, but what does that mean? Wicking refers to the travel of liquid across the fibers of a fabric. This siphoning motion differentiates wicking from absorption.

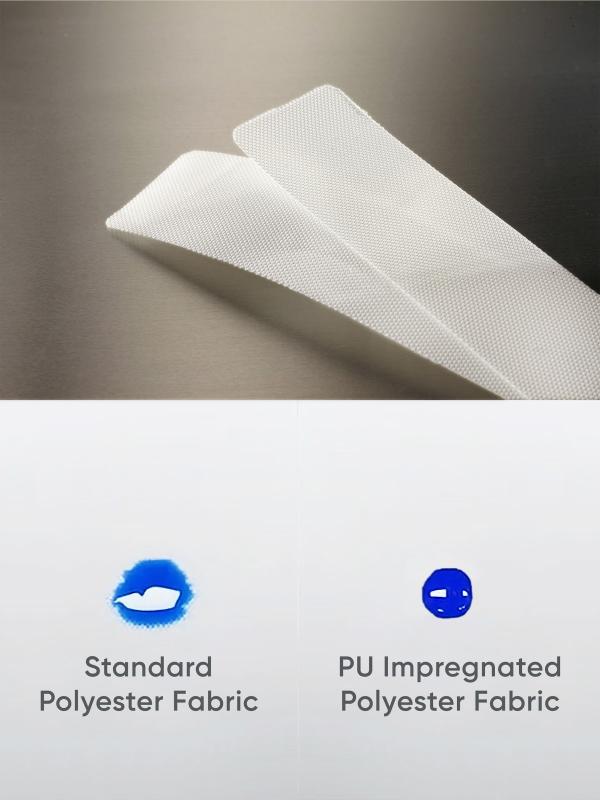

Most conveyor belts are made up of a fabric reinforcing layer and an elastomeric layer such as rubber, PVC or PU. In some applications, wicking is a desirable trait as it can prevent moisture build-up under a product, think of dough on a bakery belt. As the dough bakes, liquid begins to evaporate. The liquid then quickly disperses along the yarns of the fabric. A fabric that is treated for anti-wicking will repel liquid and it may appear to bubble up on the surface in a stationary position. Anti-wicking is desirable in many food applications because wicked liquids can carry microbes and pathogens large distances across the yarns, making them difficult to disinfect.

There are many solutions to address wicking in conveyor belts. Many of Mol Belting’s part numbers come standard with a PU impregnation as pictured to the right. Edgecap can also seal and protect the exposed ends of the belt. Homogeneous belting has no fabric. However, if strength is needed then a fabric reinforced belt with a cover on both sides and edgecap may be necessary.

Call your local sales representative to find the correct belt for your application.